STREAMLINE SERIES / CLEANING TECHNOLOGY

STREAMLINE Series

Air-screen seed cleaning machine

The Streamline is a screening machine specifically designed for the fine seed industry.

This Air-Screen-Cleaner is used for seed production lots and breeding plots – laboratory purposes and to process commercial fine seed multiplications (e.g. vegetable and flower seeds).

A wide range of screens makes the machines suitable for almost any crop.

STREAMLINE SERIES PRODUCTS BY CAPACITY

| SMALL | MEDIUM | LARGE | |

|---|---|---|---|

| STREAMLINE SERIES | STREAMLINE 50 | STREAMLINE 100 | STREAMLINE 800 |

| Total Length (mm) | 1.300 | 1.800 | 2.400 |

|---|---|---|---|

| Total Width (mm) | 1.050 | 1.050 | 1.450 |

| Total Height (mm) | 1.600 | 1.850 | 2.900 |

| Sieve Width (mm) | 400 | 400 | 800 |

| Sieve Length (mm) | 540 | 1.000 | 960 |

| Nº of sieves | 3 | 3/4 | 3 |

| Capacity (wheat kg/h) | 150 | 300 | 600 |

MAIN FEATURES

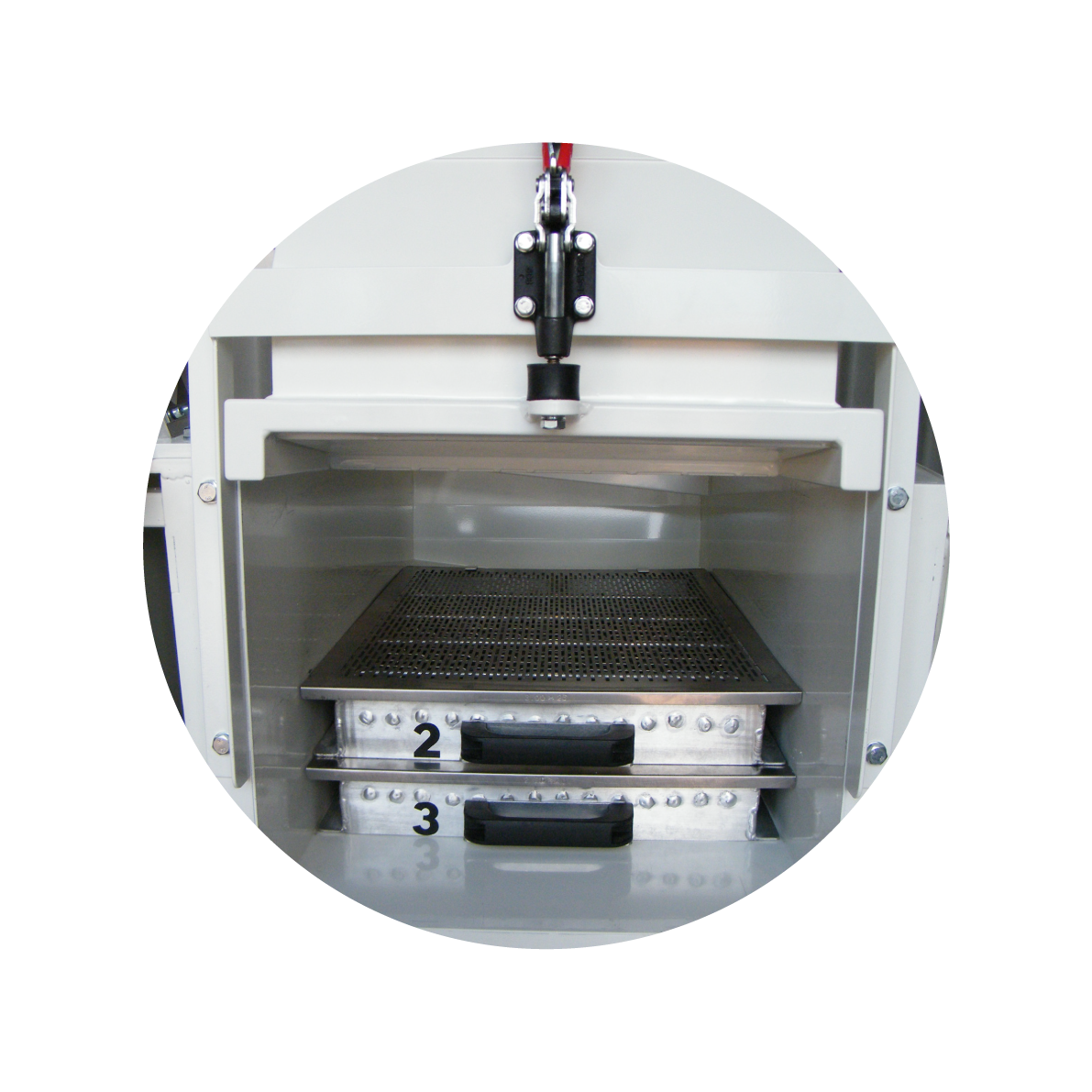

Unique screen changing system

The complete set of screens can easily be taken out of the screen compartment. The empty screen compartment ensures good and thorough cleaning and no risk of contamination.

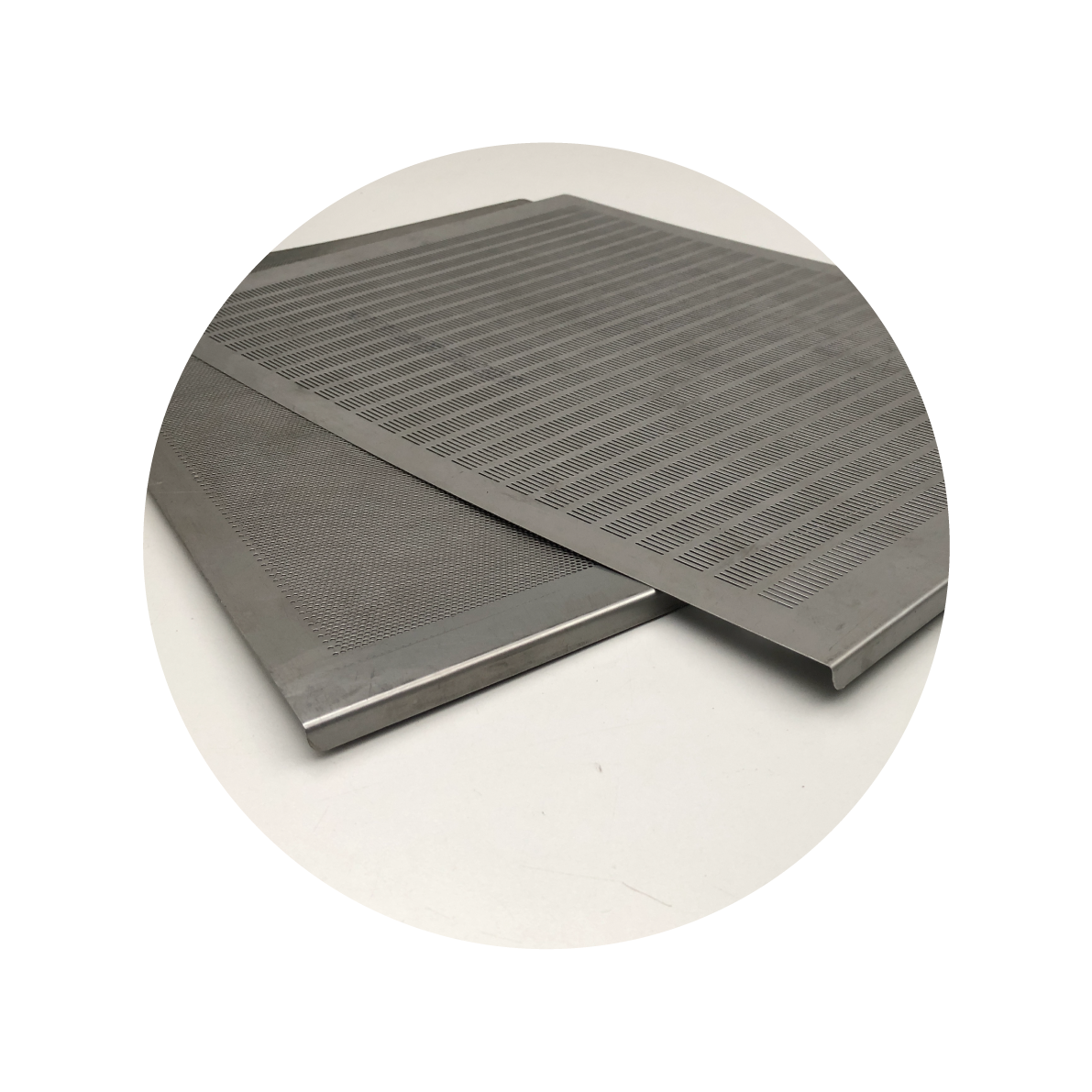

Screens free of frames

The screens used in the streamline 50 and 100 are designed in a unique way without frames. This ensures optimal cleaning and reduces the risk on contamination.

After blast air stream

Very accurate gravity separation by the after blast air stream channel. No valves; the air speed is continuously variable by a frequency converter; not connected to a second suction unit, like a pre-suction unit.

HOW DOES IT WORK?

The seeds are put into the VIDOS feeding hopper (or on the optional feeding belt), transported by the vibrating gully onto the first screen. The feeding quantity is continuously adjustable. The overflow from the first screen leaves the machine at a separate outlet. The seeds dropped through fall on the skid plate and glide back to the beginning of the second screen so the second screen is used over the hole screen length. The overflow of the second screen leaves the machine at a separate outlet, the seeds dropped through fall on the third plate where parts , smaller than desired size drop through and are eliminated through a separate outlet. The overflow seeds of the third screen have the desired size and are transported into the air stream channel.

The seeds of the desired fraction, free from impurities and sand are transported from the lower screen into the air stream channel. In this so called after blast channel the seeds are separated by gravity on specific weight. The heavy seeds with the best germination and vigour fall down in the air stream channel into a collecting box underneath the machine (optionel: or to the side of the machine by a vibrating outlet). Finally the lightest seeds and debris leave the machine at the top of the air stream channel into two separate outlets and the air is blown out and can be collected by a dust extraction hood (optional).

FEATURES

• Feeding by VIDOS vibrating feeder for a regular flow, with integrated continuously variable speed adjustment for very precise dosing. Belt feeding also possible, see “options”.

• Capacity of feeding hopper: 12 / 25 L (standard on 50-3 and 100-3), 60 L (standard on 800-3), other hopper sizes on request.

• The machine works with 3 screen levels (100-3 also available with 4 screen levels).

• The screen are kept clean during processing by rubber balls that are laying in a removable ALUMINUM ball frame underneath each screen.

• The screens are tighly fit in the machine by a central clamb-locking system for a quick changing of the screens and thorough cleaning of the machine.

• The oscillation speed of the screen compartment is continuously variable by a frequency converter, assuring optimal cleaning results

• The machine has low vibration as the screen- compartment is counter balanced.

• The speed of the cleaning fan is variable and adjusted from standstill to maximum by a frequency converter assuring very accurate cleaning and sorting of seeds. The fan has a very stable and reproducible output.

• Very low noise level compared to similar machines.

• Very easy and thorough to clean and no contamination risk, because of the open construction and because the screen compartment can be completely emptied

• No wooden or aliminum frames on the screens where seeds can stick and hide.

OPTIONS

• Belt feeding for difficult seeds to ensure a good seed flow into the machine.

• Pre-suction unit specifically designed for fine seeds. The Selecta air units are the most precisely working air units available in the market.

• Collecting the “good seeds” on the side of the machine.

• Operating panel by Touch screen.

• Collecting funnel to collect the debris from the screens (for test institutes etc.)

VIDEO

STREAMLINE SERIES / CLEANING TECHNOLOGY

All Products

-

ZZ SERIES

SORTING

-

HC SERIES

CALIBRATION

-

STREAMLINE SERIES

CLEANING

-

OS F SERIES

SORTING

-

OS P SERIES

SORTING

-

CF 04 SERIES

TREATMENT

-

POL SERIES

POLISHING

-

AS SERIES

CLEANING

-

SPIRAL SERIES

SORTING

-

GRAVITY TABLE SERIES

SORTING