OS F SERIES / SORTING TECHNOLOGY

OS F Series

Optical Sorting in a new way

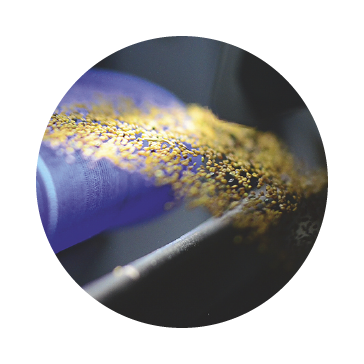

The new ROEBER OS F allows to clean small seeds at highest quality level where nowadays standard color sorters fail. The innovative material transport system is well synchronized with the newly developed ejection system. A high resolution full color camera system based on latest high-tech optical components detects tiny differences to ensure purest fine seed lots. The OS f is scalable to provide you with the sorting width and capacity you require for your processing line.

OS F SERIES PRODUCTS BY CAPACITY

| SMALL | MEDIUM | LARGE | |

|---|---|---|---|

| OS F SERIES | OS F 1.6 roeber | OS F 3.0 roeber | Ask us about your requirements |

| Length (mm) | 1.767 | 1.767 | |

|---|---|---|---|

| Width (mm) | 820 | 820 | |

| Height (mm) | 1.931 | 1.931 | |

| Sorting Width (mm) | 160 | 300 | |

| Power consumption (kVA) | 0.9 | 1.4 | |

| Power supply | 230 V AC. 50 Hz | ||

| Required Air Flow | min. 0.15 m3 per min.*at 2.5 bar | ||

| Internet Access | LAN-Ethernet-Cable | ||

MAIN FEATURES

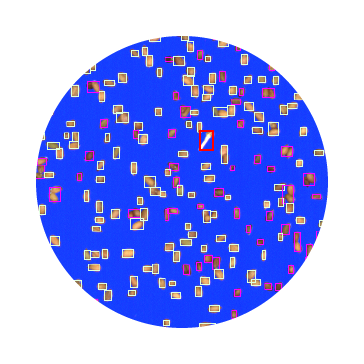

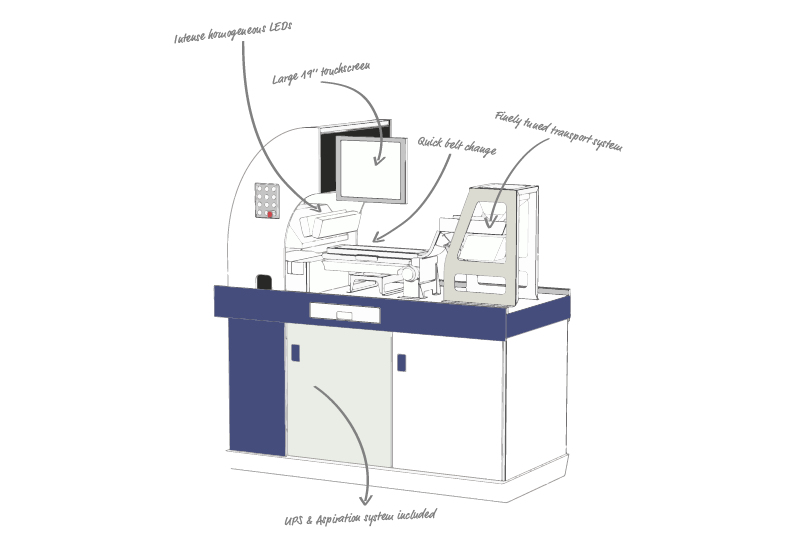

Optics at a New Level

The ROEBER transport system optimally presents the product to the inspection unit where it is scanned by a high resolution and innovative light and optics combination. With this new technology we are able to inspect small objects like vegetable seeds or at the same time large objects like wheat – both with excellent full color image quality. The high contrast allows to distinguish tiny differences which is the basis for high quality sorting. Details of the small seeds are easy to see and can well be evaluated on the large 19” touchscreen.

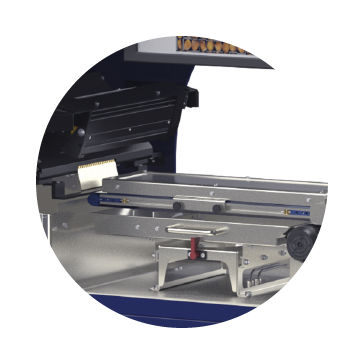

Smallest Nozzles - Optimal Ejection

The OS F has got a new ejector-nozzle technology with an interval of 2 mm. The precision on ejecting small seeds is therefore considerably higher than others on the market. The high-speed valves eject bad objects precisely with a very small jet stream interval to achieve utmost separation of good and bad particles. This new ejection system yields highest sorting quality while reducing the loss of good product.

TeachNSort Smart+

The new software combines easy automatic teach-in functionality with a manual re-adjustment or amendment functionality. It takes the fact into account that not only nature is diverse but users have in addition different requirements. It makes life easy where it is possible and accounts for complexity where unavoidable. While the OS f is active in production, the next product can be prepared offline at the office PC. OS f easily and quickly.

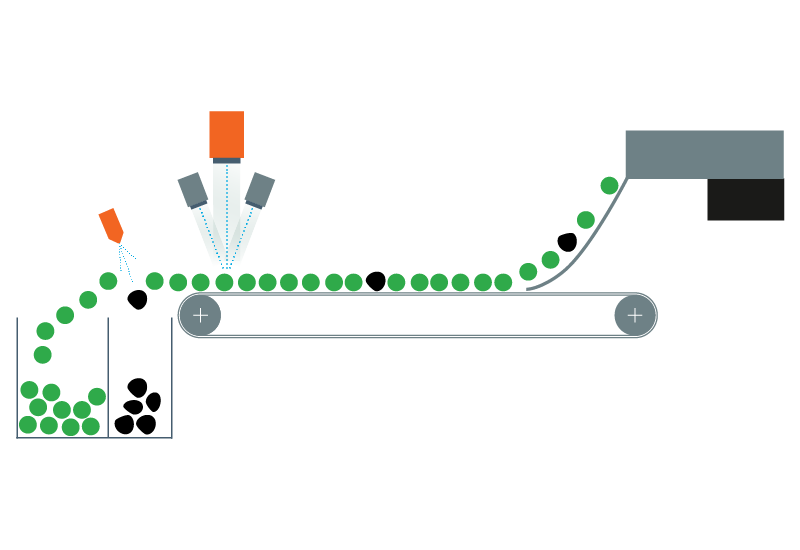

HOW DOES IT WORK?

Seeds smaller than 1 mm are transported from the feeder along a stainless steel chute down to a specially designed conveyor belt system to be scanned at the end and ejected nearly immediately behind the inspection line. Of course, the seeds are also allowed to be bigger than 1 mm.

Because of the special feeding system, the seeds can be round and tumbling or flaky or arbitrarily shaped. This makes the sor ting system applicable to an enormous range of products.

The high-speed valves eject bad objects precisely with a very small nozzle interval to achieve utmost separation of good and bad particles. This new ejection system yields highest sor ting quality for small objects while reducing the loss of good product.

FEATURES

• Full color inspection

• Shape detection

• Sophisticated object splitting

• Kernel-by-Kernel analysis

• Automatic & manual & mixed-mode teach-in

• Capacity Measurement

• Changeable Background Color

• Easy and quick to clean due to its open design

• Quick belt change

VIDEO

OS F SERIES / SORTING TECHNOLOGY

All Products

-

ZZ SERIES

SORTING

-

HC SERIES

CALIBRATION

-

STREAMLINE SERIES

CLEANING

-

OS F SERIES

SORTING

-

OS P SERIES

SORTING

-

CF 04 SERIES

TREATMENT

-

POL SERIES

POLISHING

-

AS SERIES

CLEANING

-

SPIRAL SERIES

SORTING

-

GRAVITY TABLE SERIES

SORTING